Summary of the Project

Unique Group completed the 5-year maintenance, and overhaul on an SPHL and Launch & recovery system with re-installation of the complete system on the vessel.

Client Requirement

The client had requested for the maintenance and re-installation of the Unique Group’s Oceanwide brand SPHL and Launch & recovery system (LARS) which was set up originally on their Dive support vessel.

Challenges faced

The SPHL was delivered from Unique Group’s Netherlands office and the maintenance had to be performed from our Singapore facility which required a collaborative technical partnership between our two offices to complete the maintenance within the client stipulated deadlines.

Unique Solution delivered

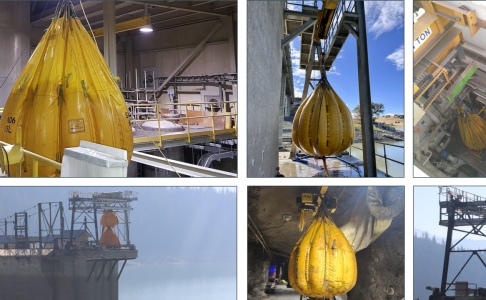

Unique Group started the maintenance with an initial assessment of the SPHL and the LARS in the DSV, this helped the team plan the maintenance activities and schedule the project to ensure timely delivery to the client.

The first phase constituted of dismantling the system and preparing it for sandblasting and painting, the second phase involved the installation of the parts to be replaced and the painting of the system. The third and final phase was the installation of the system back on the DSV, ready for use by the client.

Benefits delivered

- Cost and time saving: With Unique Group’s global presence we were able to service the client requirement by utilising the synergy between our Netherlands & Singapore offices thus offering a cost-effective solution for the client.

- Customised approach: The maintenance of the system was planned according to the client’s needs and IMCA regulations.

- Project completed within the timeframe

- Fully HSEQ compliant with zero incidents