Unique Group, global leaders in subsea technologies and engineering, has successfully supported one of the longest and most technically complex shore pull operations undertaken for ADNOC’s Hail and Ghasha offshore gas development, working in close collaboration with Saipem.

Project Scope and Industry Significance

The scope included three individual shore pulls, each exceeding 6.67 kilometers, placing them among the longest shore pulls ever executed in Saipem’s history and within the offshore industry globally. The operation demanded precise engineering coordination to ensure controlled tension, stability, and safe equipment performance throughout the installation.

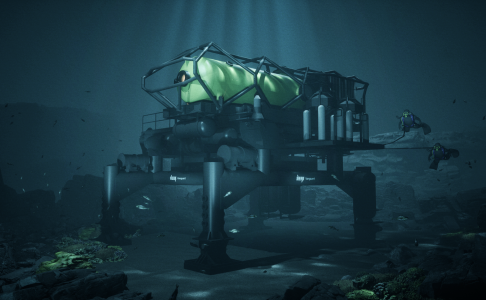

Engineered Shore Pull Buoyancy Solution

A carefully engineered configuration of shore-pull wires and bespoke buoyancy systems was deployed to maintain load control and ensure all operational parameters remained within strict safety limits across the extended pull lengths.

As part of the pipelay scope, Unique Group designed, engineered, and supplied custom-made 5-tonne Inflatable Buoyancy Units (IBUs) and 1-tonne Mono Buoyancy Units (MBUs). These enclosed buoyancy devices are uniquely suited for complex shore pull and towing operations, combining the load-angle tolerance of parachute-type bags with a single-point attachment design. This enables the MBUs to be installed in line with the load and safely pulled through, offering superior control and operational flexibility in constrained environments.

Technical Challenges and Tailored Engineering Solutions

The project presented several significant technical challenges, requiring a highly tailored engineering approach. The narrow and shallow trench geometry restricted available space, necessitating a bespoke buoyancy configuration to maintain stability during installation. In parallel, the Pressure Relief Valve (PRV) system was specifically engineered to accommodate tidal variations in the nearshore environment, ensuring consistent buoyancy performance and operational safety throughout the shore pull.

Close Engineering Collaboration with Saipem

Unique Group worked closely with Saipem’s engineering and project teams to adapt both the MBU configuration and PRV design to site-specific conditions. These modifications were critical to mitigating risk, maintaining installation efficiency, and ultimately achieving a successful shore pull under demanding constraints.

Leadership Commentary

“This was a complex shore pull with very tight environmental and physical constraints,” said Rakesh Bangera, Head of Sales – Middle East at Unique Group. “Our team worked closely with Saipem to develop a bespoke buoyancy solution that addressed trench limitations, tidal variations, and long pull distances. This project is a strong example of how our engineering agility and collaborative approach help clients overcome challenging offshore installation scenarios.”

Saipem highlighted the value of close technical collaboration in delivering the operation successfully.

“The Hail and Ghasha shore pull required precise engineering and a high degree of adaptability,” said Suraj Kalase, Project Lead, Saipem. “Unique Group’s ability to tailor the buoyancy design to the project’s specific constraints played a key role in achieving a safe and successful installation.”

About the Hail and Ghasha Development

The Hail and Ghasha development is a flagship offshore gas project for Abu Dhabi and is designed to set new benchmarks in sustainability. The project integrates innovative decarbonisation technologies into a single, integrated solution, capturing 1.5 million tonnes per annum (mtpa) of CO₂, while supporting the production of low-carbon hydrogen and leveraging clean power from nuclear and renewable energy sources.

Reinforcing Unique Group’s Role in Offshore Energy Projects

Unique Group’s contribution to the project reinforces its role as a trusted engineering partner for complex offshore and nearshore operations, supporting clients in delivering critical energy infrastructure while aligning with the industry’s transition to lower-carbon solutions.