Cranes are integral to a wide range of industries, including oil and gas, energy, and general manufacturing. To maintain safety and efficiency, it’s crucial to prioritize the inspection and maintenance of critical crane components, especially wire ropes. Following are the key aspects of wire rope inspection, safety regulations, and the innovative approach to crane maintenance and testing, including

Magnetic Resonance Testing (MRT) capabilities from Unique Group’s Water Weights®, for enhanced safety and reliability. The durability and reliability of wire ropes are paramount for the safe operation of industrial cranes. Regular inspections and maintenance play a critical role in preventing accidents, minimizing downtime, and extending the life of these essential assets. Periodic Inspections are comprehensive examinations conducted at regular intervals, such as monthly or quarterly depending on the crane’s duty cycle. Any new or altered cranes, especially on load bearing components require thorough inspection of the wire rope as part of the compliance process.

Wire rope inspections involve a combination of visual and physical assessments. Visual inspections examine the entire length of the wire rope for visible signs of wear, damage, or corrosion, while physical or touch inspections examine the wire rope by running hands along its length to detect abnormalities.

Understanding wire rope strength and classifications is essential during compliance inspections. Wire rope strength or its ability to withstand loads is typically expressed as breaking strength, the maximum load a wire rope can bear before failure. Wire rope classifications are categorized based on factors like construction, diameter, and material. Common classifications include 6×19, 6×37, and 8×19, reflecting the number of strands and wires in each strand.

Regular wire rope maintenance is crucial for several reasons:

- Safety: Prevents accidents by identifying potential issues.

- Productivity: Maintains efficiency and minimizes downtime.

- Cost Savings: Extends wire rope lifespan, reducing replacement costs.

- Regulations and Safety Critical Points

Safety regulations are essential for safety in crane operations. Regularly inspect wire ropes for wear, damage, and corrosion. Compliance with industry standards such as ASME (American Society of Mechanical Engineers) and ISO 4309 is crucial for wire

rope inspections. Other aspects of importance include:

- Hooks and Fittings: Ensure these components can safely handle loads.

- Load Monitoring Systems: Accurate load monitoring prevents overloading.

- Boom and Structural Components: Inspect for cracks, deformation, or weakness.

- Electrical Systems: Check controls and wiring for faults.

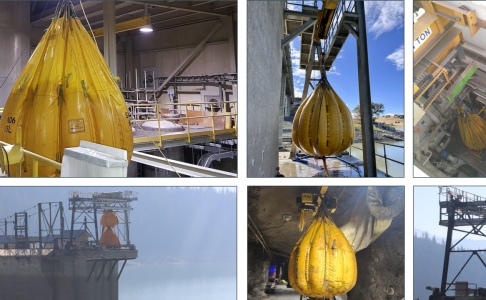

Magnetic Rope Testing (MRT) from Unique Group’s Water Weights®

In addition to visual and physical inspections, our holistic approach to crane maintenance and testing includes advanced technologies like Magnetic Resonance Testing (MRT) from Water Weights®. MRT capabilities allow inspectors to see inside the wire rope’s core, detecting issues that are not visible externally.

The software that provides the operating backbone for the tool itself also allows the user to track faults over time and chart or graph the faults. A manufacturing engineer could relate the appearance of faults to environmental and operational factors that may be influencing the rope’s lifespan.

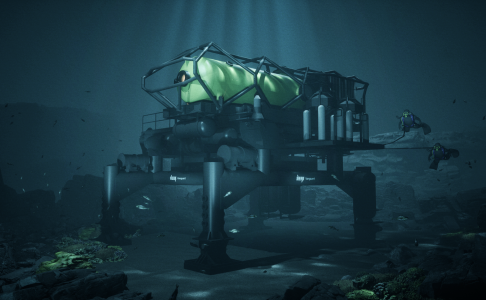

By utilizing Water Weights® bags, MRT capabilities, and integrated load measurement technologies, crane operators and maintenance personnel can conduct inspections and testing effectively, meeting regulatory requirements, and enhancing overall crane compliance, safety, and reliability. Our holistic approach encompasses an ever-growing technological list of solutions as part of a toolbox for customers. The suite of tools in the box offers a comprehensive solution for crane testing, ensuring enhanced safety, and reliability in various industries and sets the company apart from other load testing providers.