Summary of the Project

The E& P client engaged Unique Group in Singapore to support a critical maintenance operation on a buried subsea Pipeline End Manifold (PLEM) located in shallow waters near an estuary in Bangladesh. The site had experienced significant sedimentation due to constant exposure to harsh currents and seabed movement, resulting in the PLEM being fully buried by sand and silt.

Client Requirement

The client required the deployment of a high-performance excavation system capable of quickly de-burying the PLEM to provide safe and effective access for divers tasked with conducting essential maintenance operations.

Challenges Faced

The operation was particularly challenging due to:

- Extremely strong currents, which reduced diver activity window.

- Short and irregular workable windows between high and low tides.

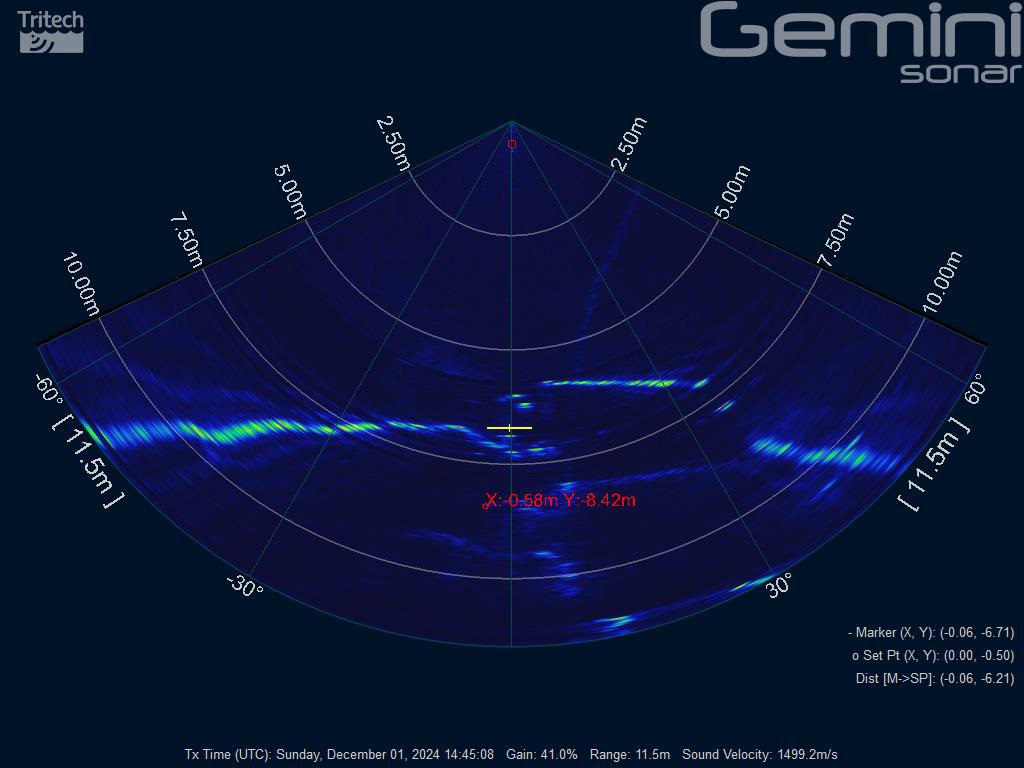

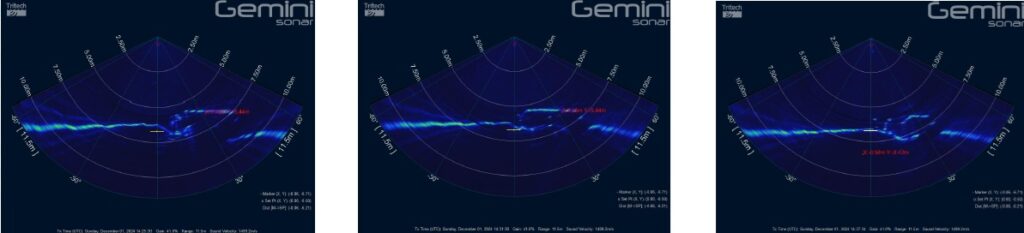

- Reduced underwater visibility, adding to the complexity of both the excavation and dive operations.

These environmental conditions demanded a flexible, efficient and rapid-response excavation solution to align with the tight operational windows.

Unique Solution Delivered

Unique Group deployed its controlled mass flow excavation system, the Uni-FlowX, coupled with a custom Launch and Recovery System (LARS) specifically engineered to handle rapid deployment and retrieval in harsh environments. The system allowed:

- High-volume, non-intrusive excavation of sediments around the buried PLEM.

- Fast mobilization to align with tidal shifts.

- Safe and quick tool recovery during weather or tide-induced interruptions.

Unique Group’s deployment of the Uni-FlowX and LARS systems provided a precise, rapid and highly adaptable solution under challenging environmental conditions. The success of this project showcases our ability to deliver advanced subsea support even in shallow, high-current and visibility-limited scenarios — reaffirming our position as a trusted partner in offshore infrastructure maintenance.

Benefits Delivered

- Enhanced operational efficiency by fully utilizing the limited tidal windows.

- Reduced diver exposure time, contributing to safer operations.

- Minimized project downtime through rapid excavation.

- Improved maintenance access, allowing the client to perform necessary work without delays or need for further excavation.