Summary of the Project

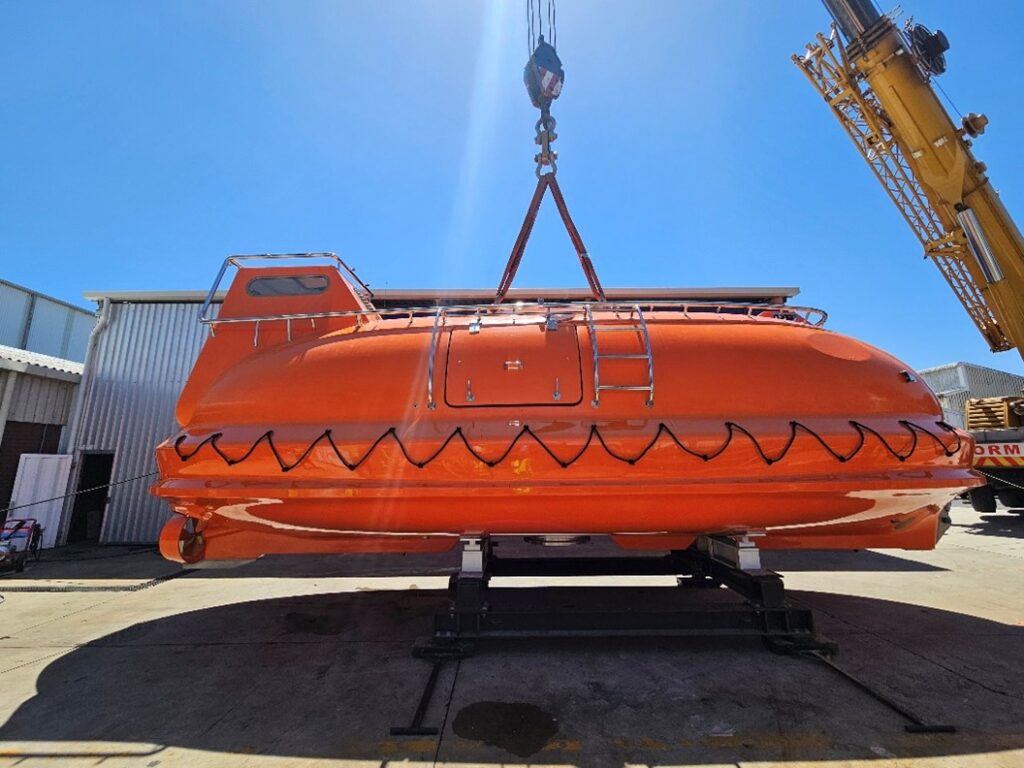

Unique Group successfully completed the design and delivery of a DNV-classed 12-man Self-Propelled Hyperbaric Lifeboat (SPHL) with a RIINA classed Hyperbaric system and DNV-approved Davit system.

Client Requirement

A European client commissioned Unique Group to design and deliver a fully certified 12-man SPHL, as part of a broader saturation diving system solution. Key client requirements included:

- A RINA-classed hyperbaric lifeboat, with a certified capacity of 12 occupants under pressure.

- A DNV-type- approved lifeboat designed for 4 crew and 72h autonomous life support capability for chamber occupants.

- A DNV-type-approved Davit launching system, enabling deployment from either the port or starboard side of a vessel.

- Compliance with IMCA standards.

- Approval and classification for the chamber and life support systems by DNV, with pressure vessel construction standards in line with ASME VIII Div-2 and ASME PVHO-1.

This project stands out as it’s Unique Group’s first RINA-classed build globally making quality and compliance non-negotiable.

Challenges Faced

- The project included Factory Acceptance Tests (FATs) and sea trials with RINA and DNV surveyors in early 2025—demanding high levels of precision and performance.

- This was the first SPHL built in Unique Group’s Cape Town facility; to facilitate a seamless delivery the team was provided on-site training and guidance by technical specialists from Unique Group’s Netherland’s facility, ensuring compliance with the technical demands of a RINA-classed build.

Unique Solution Delivered

Unique Group designed, engineered and manufactured a SPHL system meticulously aligned with global safety, class, and operational standards. Highlights of the solution include:

- Hyperbaric Evacuation Capability:

The SPHL was designed to facilitate the safe transfer of up to 12 divers under pressure from a saturation diving system directly into the onboard hyperbaric rescue chamber. The system ensures full under-pressure transfer and independent life support for a minimum of 72 hours post-evacuation.

- System Integration and Portability:

The SPHL system—including the lifeboat, rescue chamber, ancillary equipment, and davit—was engineered as a transportable modular unit that can be installed on either port or starboard side of a DSV or barge.

- Compliance and Certification:

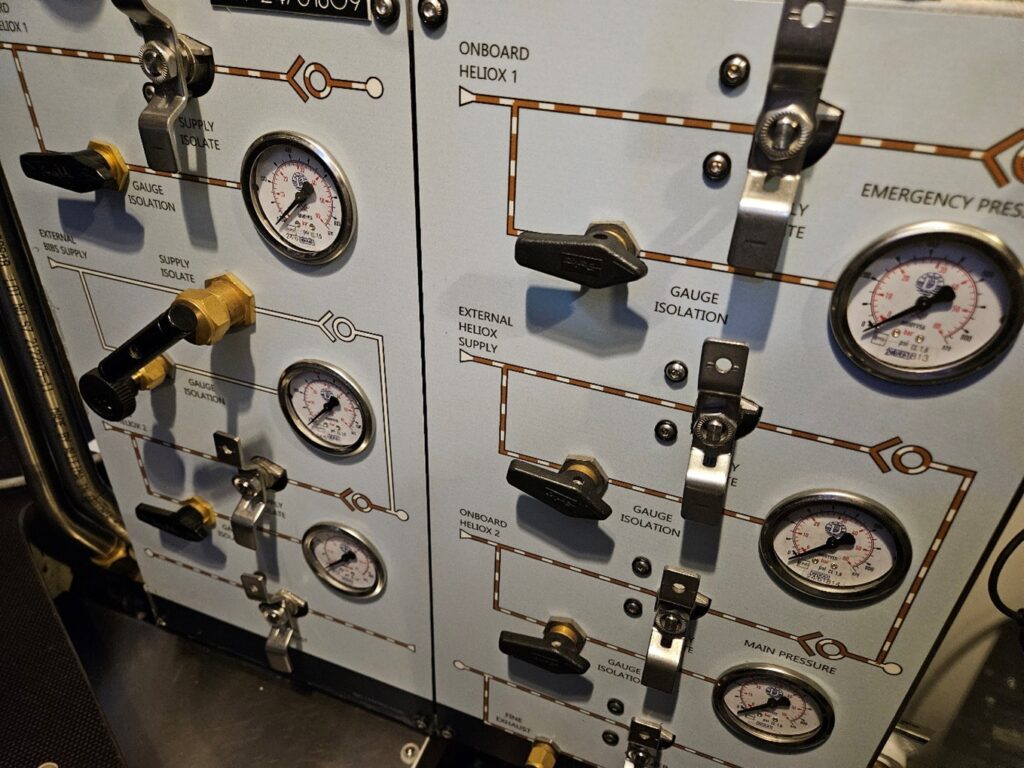

Chamber & Life Support System: These were RINA-approved and ASME-compliant (ASME VIII Div-2, PVHO-1).

FMECA (Failure Modes, Effects, and Criticality Analysis): to meet safety-critical analysis protocols.

Design Verification: A comprehensive compliance matrix was developed and validated against DNV, RINA and IMCA standards.

- Major Components:

Self-Propelled Lifeboat with integrated life-support and navigation systems.

Hyperbaric Rescue Chamber rated for 300 msw.

DNV-certified Davit Launching System.

- Operational Features:

Independent propulsion, power generation, and navigation capability.

Reinforced bow towing point for ramp recovery and emergency towing.

Single-point lifting for efficient vessel handling.

All towing and hoisting operations can be performed from the internal steering dome, eliminating external risk during emergencies.

Benefits Delivered

- Digital Engineering Excellence: The entire SPHL unit was 3D scanned, generating a digital twin to support maintenance, training, and future builds within the Unique Group.

- Client Satisfaction: Based on the build quality and project performance, the client placed a follow-up SPHL order in Q4 2024, to be delivered in 2026.

- Compliance-Ready for Broader Market: With DNV, RINA, IMCA and ASME standards integrated, the SPHL is deployable across both commercial and military sectors globally.

- Global Capability Expansion: Successful transfer of SPHL production capabilities from Unique’s Netherlands facility to South Africa, positioning Unique Group as a certified global manufacturing partner for future projects.

Unique’s client has reaffirmed their trust in Unique Group by placing a follow-up order in December 2024 for another SPHL delivery in January 2026, reinforcing the value and reliability of the solution provided.