Non-Destructive Testing (NDT) services ensure safety, reliability, and compliance in offshore, marine, and industrial projects. From ultrasonic and magnetic particle testing to spark testers and cathodic protection checks, the right provider helps detect flaws without damage, extend asset life, and meet global standards. Unique Group offers field-ready NDT tools, certified technicians, and global support to deliver accurate inspections in any environment.

Key Takeaways

-

Critical for Offshore & Industrial Safety: NDT services detect flaws early to prevent costly failures and downtime.

-

Wide Range of Methods: UT, MPI, Spark Testing, CP monitoring, and more—tailored to inspection goals and environments.

-

Unique Group Advantage: Certified tools (Cygnus, Buckleys, ASAMS), global presence, and bundled NDT kits for fast deployment.

Introduction

Non-destructive testing (NDT) services help detect defects such as surface flaws, internal cracks, or corrosion, without causing damage to the components being tested, ranging from subsea pipelines to manufacturing plants.

However, finding the right NDT inspection services provider is all about their ability to deliver safe and efficient operations through both advanced techniques and reliable equipment.

This guide breaks down the major NDT techniques, essential technologies, and factors to help you choose the right inspection services provider.

You’ll also see how Unique Group’s comprehensive range of non-destructive testing equipment and service capabilities supports your project needs.

Role of NDT Services in Offshore and Industrial Projects

Harsh environments, high-risk applications, and strict safety standards make NDT services non-negotiable for industries like oil & gas, marine, and manufacturing.

- Inspection in extreme conditions: Offshore NDT must withstand subsea pressure, temperature shifts, and limited access environments.

- Regulatory compliance: Standards such as ISO and ASME require periodic inspections and documented traceability.

- Predictive maintenance: NDT methods allow early detection of defects like wall thinning or coating failure before they lead to shutdowns.

- Asset life extension: Routine NDT testing of pipelines, tanks, and structures helps extend their operational lifespan while maintaining safety.

When integrated early in the project lifecycle, NDT services become an enabler of performance, not just a post-failure checkpoint.

Essential NDT Testing Methods You Should Know

The appropriate testing approach is determined by the type of material, the purpose of the inspection, and the conditions in which it will be carried out.

1. Ultrasonic Testing (UT) and Phased Array (PAUT)

Ultrasonic testing is a core non-destructive testing technique used to identify internal flaws, detect weld defects, and perform accurate thickness measurements across assets. UT uses high-frequency sound waves to identify flaws beneath the surface, without harming the tested material.

Where it’s used:

This method is widely applied in pipeline integrity assessments, high-pressure vessels, and structural welds in offshore rigs and manufacturing plants. Phased Array Ultrasonic Testing (PAUT) further enhances precision by scanning with multiple angles.

Unique Group offers the Cygnus Ultrasonic Thickness Gauge Series, including Cygnus 4+, 6+ PRO, and ROV-compatible models. These tools are designed for both topside and subsea applications, delivering real-time data for improved inspection reliability.

2. Magnetic Particle Testing (MT)

Magnetic particle inspection is used for detecting surface flaws and shallow defects in ferromagnetic materials. The method works by magnetising the component and introducing magnetic particles, which gather around any irregularities.

Where it’s used:

MT is ideal for weld inspection during fabrication or shutdown periods, especially for offshore structures, pressure vessels, and industrial steel components.

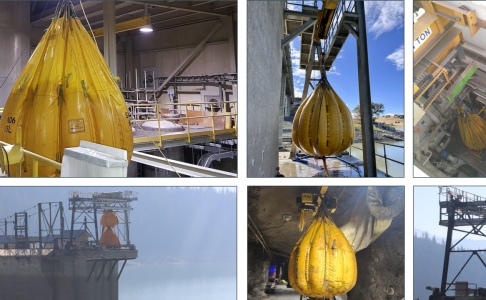

Built for offshore NDT campaigns, Unique Group’s ASAMS System 3 is a rugged magnetic particle inspection unit engineered from stainless steel.

With continuous ink agitation, dual AC/DC magnetisation, and a lightweight profile in seawater (just 26 kg), it supports both diver-held and ROV-assisted deployment during time-sensitive inspection operations.

3. Spark Testing for Coating Integrity

Spark testing is a non-destructive technique used to identify coating defects like pinholes, cracks, and areas of porosity. By applying a controlled voltage across the coating, operators can verify the presence of discontinuities that may otherwise lead to pipeline failure.

Where it’s used:

Spark testing is important for inspecting coated tanks, buried pipelines, and waterproof membranes across various industries, including oil & gas, marine, and civil infrastructure.

Unique Group supplies Buckleys PST-100 Spark Tester Kits in multiple configurations—Basic, Standard, and Complete. Designed for rugged industrial use, these testers offer adjustable voltage output and integrated safety features, ensuring compliant field inspections.

4. Cathodic Protection Checks

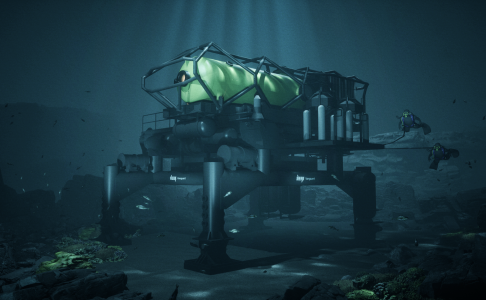

Cathodic protection (CP) monitoring is a preventive inspection strategy to assess the performance of corrosion control systems on subsea metallic assets. By measuring voltage potentials, CP checks ensure that sacrificial or impressed current systems are actively protecting pipelines and infrastructure.

Where it’s used:

This technique is vital in subsea environments where structures like risers, jackets, and pipes are exposed to harsh conditions. Routine CP testing helps maintain pipeline integrity and prolongs asset life.

Unique Group’s BathyCorrometer® Pro Mk7 is a trusted industry-standard for underwater CP inspection. It provides accurate readings even in challenging marine environments and is compatible with long-reach flexible probes.

When paired with UCP1A/B CP Probes and calibration kits, it delivers a complete corrosion monitoring solution.

5. Dye/Liquid Penetrant, Eddy Current, and Radiographic Testing

These are specialised non-destructive testing methods used to identify surface flaws and internal defects in complex or hard-to-access materials. Each technique offers advantages depending on the component and inspection environment.

Where it’s used:

-

- Dye Penetrant Testing (DPT): Well-suited for detecting surface-breaking flaws on smooth, non-absorbent materials.

- Eddy Current Testing: Suitable for detecting subsurface flaws without removing coatings, especially in tube inspection or weld verification

- Radiographic Testing (RT): Best for internal imaging of castings, welds, and structural components where dimensional accuracy is necessary.

While some of these techniques may not require bulky equipment, they are often included in Unique Group’s integrated NDT services packages. Their expert teams help select the right technique and tools depending on material type, accessibility, and compliance requirements.

The Advantage of Multi-Tool NDT Service Providers

Why Single-Method NDT Testing Isn’t Enough?

Offshore and industrial systems are rarely uniform. You’ll often need to detect surface flaws, subsurface voids, and internal defects, all in the same campaign. That’s why relying on a provider offering only one or two techniques can compromise your inspection results.

Value of Integrated NDT Equipment Kits

Complete inspection kits streamline workflows and reduce on-site complexity. Unique Group offers field-ready kits combining:

- Spark testers + reference cells

- Magnetic particle units + calibration kits

- Ultrasonic thickness gauges + diver/ROV-compatible accessories

This level of integration ensures efficient operation during asset inspection and maintenance.

Field-Ready Tools for Industrial & Offshore Use

Unique Group’s equipment is built for rugged conditions:

- Lightweight and portable designs

- Subsea-rated housing and cables

- Modularity for confined or remote-access inspections

Every tool is built with efficiency, integrity, and safety in mind, from vacuum box testing to ultrasonic crawlers.

What to Look for in NDT Inspection Services Providers

Selecting the right provider for NDT services goes beyond tool availability. It’s about trust, traceability, and technical depth. Here’s what project managers and engineers should prioritise:

Expertise and Certifications

Choose service partners whose technicians are certified under globally recognised standards like:

- ISO 9712, PCN, and ASNT Level II/III

- Specialised certifications in offshore NDT procedures or welder qualification assessments for ensuring inspection accuracy in high-risk environments.

- Practical field experience in energy, marine, and industrial environments

Expertise matters just as much as the equipment, especially when working in high-risk or regulated zones.

Safety, Accuracy & Compliance Focus

Compliance isn’t optional in critical infrastructure. Your provider must prioritise:

- All equipment is routinely calibrated following certified, traceable standards to ensure accuracy and compliance.

- Aligned documentation with ASME, DNVGL, or client-specific procedures

- Live data collection and fully auditable reporting across all NDT testing tasks

This ensures that inspections detect defects and support regulatory compliance and insurance audits.

Rapid Mobilisation and Technical Support

Downtime is costly. A trusted NDT services provider must ensure:

- Regional stock hubs for fast equipment mobilisation

- On-call technical teams for field setup and troubleshooting

- Expert assistance with interpreting test results to prevent misdiagnosis

With Unique Group’s presence in global locations, field support is always close by.

Evaluating the Equipment Behind the Services

Even the best-trained technician is only as effective as the tools they use. Here’s what to evaluate when comparing service providers.

Equipment Calibration, Modularity, and Compatibility

- Look for regularly calibrated equipment with digital readouts and remote logging capability.

- Ensure tools are modular, compatible with ROVs, diver deployment, or confined-access tooling.

- Choose systems designed for subsea durability, high-frequency current testing, and rugged environments.

Unique Group’s Offerings

Unique Group is a global leader in non-destructive testing equipment. Key products include:

- ASAMS System 3: A magnetic particle inspection unit featuring continuous ink agitation, durable stainless-steel construction, and both AC/DC magnetisation modes.

- Buckleys PST-100 Spark Testers: Engineered to evaluate coatings on pipelines, tanks, and geomembranes with accuracy and dependability.

- BathyCorrometer® Pro Mk7: For underwater corrosion monitoring—field-proven across offshore industries.

- Calibration Kits, Reference Cells, UCP1A/B Probes: Ensure traceability, reliability, and regulatory compliance.

We also offer comprehensive inspection, recertification, and management services to ensure the safety, reliability, and compliance of your lifting equipment. Certified Lift Inspection & Testing – LEEA & LOLER-trained technicians provide certification for lifting accessories, cranes, winches, and back deck equipment.

These tools offer unmatched performance across industries, even if it’s pipeline integrity, corrosion mapping, or weld inspection.

How to Match Your Project Needs with the Right NDT Services Package

A strategic approach to NDT inspection services means knowing exactly what you need and customising a kit or campaign around it.

1. Define Your Project Scope

Start by identifying:

- Type of asset (e.g., subsea pipeline, tank, riser, structural beam)

- Inspection objective (flaw detection, thickness measurement, integrity check)

- Accessibility (confined space, Deepwater, overhead)

Equally important is the operational environment. Check if it’s a marine setting, a chemical plant, or a tight industrial enclosure because each comes with its own safety risks and equipment compatibility requirements.

2. Select Required NDT Methods

- Surface flaws – Consider dye penetrant or magnetic particle inspection.

- Internal flaws – Use ultrasonic testing or radiographic methods for accurate subsurface evaluation.

- Coating integrity – Use spark testers.

- Corrosion under insulation (CUI) – Think eddy current testing.

While one-off testing might suffice for minor repairs, complex projects benefit from full-scope inspections. These combine multiple NDT methods to give a holistic view of asset integrity, essential for long-term maintenance planning and risk mitigation.

3. Build a Customised NDT Kit

Unique Group offers bundled solutions tailored to your operational environment, such as:

- MT + spark tester + calibration kit for dependable pipeline integrity inspections.

- UT gauges + ROV mount + CP probes for offshore inspection

- Dye, eddy current, and vacuum box tools for comprehensive tank floor assessment.

Each kit comes ready for deployment, minimising preparation time.

4. Confirm Deployment Readiness

Before mobilising, verify:

- Tool size, weight, and transport method

- Power requirements and cable lengths

- Software/data compatibility with your digital inspection platforms

- Skill level of your team or outsourced operators

This ensures safe and efficient operation from the moment the tool hits the worksite.

Final Checklist: Choosing the Right NDT Services Provider

Before signing off, ask yourself:

- Do they provide a complete suite of NDT services and field-ready equipment?

- Are their tools certified, calibrated, and compatible with your application?

- Do their technicians hold valid certifications for your industry sector?

- Can they deliver customised kits or full-service inspection support?

- Are they equipped for offshore NDT environments and logistics?

Ticking all these boxes ensures your inspection campaigns are compliant, reliable, and efficient.

Why Choose Unique Group

Unique Group is your solutions partner.

- Single-source provider for non-destructive testing tools, accessories, and service support

- Field-trusted tools from brands like Buckleys and our in-house innovations like the ASAMS System 3

- Worldwide presence enabling quick deployment and on-ground technical assistance

- Ability to customise kits to match your inspection goals, no matter for destructive testing, welder qualification, or ongoing maintenance

Our NDT solutions are engineered for performance, durability, and compliance, ranging from vacuum box testing to subsea corrosion surveys.

Conclusion

Offshore and industrial environments demand accuracy, durability, and expertise. By combining high-quality equipment with certified NDT services, you get a package that not only detects defects but ensures your operations remain safe, reliable, and efficient.

Unique Group is ready to support your inspection strategy with the right tools, techniques, and team, wherever your project is based.

Ready to get started? Contact our NDT experts today to discuss your project scope and get a tailored solution that performs in the field.

Frequently Asked Questions

What are the most common NDT services used offshore?

Ultrasonic testing, magnetic particle inspection, cathodic protection monitoring, and spark testing are frequently used for subsea pipelines, welds, and coating evaluations.

How can I select the right equipment for NDT testing?

Start with your inspection goal: surface flaws, internal defects, or material thickness. Then consult providers like Unique Group to recommend compatible, field-ready equipment.

What’s included in Unique Group’s NDT kits?

Kits include certified tools (e.g., ASAMS System 3, Buckleys PST-100), accessories like calibration kits and cables, and often reference cells for traceability and safety.

Are NDT tools from Unique Group certified and calibrated?

Yes. All tools are supplied with valid calibration certificates and conform to ISO and offshore inspection standards.

What’s the difference between spark testing and ultrasonic testing?

Spark testing identifies defects in surface coatings (e.g., porosity, pinholes), while ultrasonic testing detects internal flaws or wall thickness issues within the material.