Summary of the Project

Unique Group’s Buoyancy & Ballast division completed a 1760 MT load test on a derrick crane of M/s Valentine Maritime owned vessel, DLB 1600 Derrick Pipelay Barge.

Client Requirement

The client approached us with a requirement to perform proof load testing for the derrick crane on their vessel DLB 1600 Derrick pipelay barge prior to it being mobilised for a project.

Challenges Faced

The COVID-19 pandemic travel restrictions were a challenge that we overcame with prior planning and constant discussions with the client.

Unique Solution Delivered

Unique Group’s Water Weights team provided a complete turnkey solution inclusive of expert technical support along with lift design and planning.

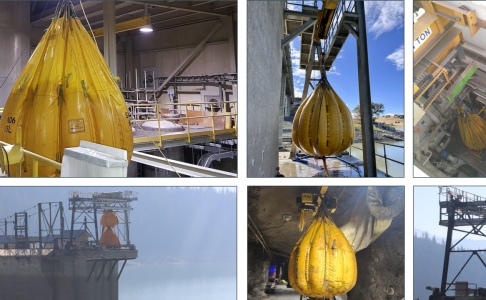

The entire load was achieved using 18 Water Weights and Seaflex WaterLoad bags of capacity 35t, 100t and 110t, our 110t bags are the largest water bag available on the market and best suited for heavy load testing applications.

A revolving load test was completed at 1320 MT and the total lifting height of the proof load test was marked at 65m. Throughout the project, the filling and emptying of the water in the bags was controlled through the supplied manifold and valve systems.

Benefits Delivered

- HSEQ Compliant and safe execution of the project

- Quick response to client needs

- Specialised technical support onsite

- Efficient and cost-effective

- Customised turnkey solution based on client requirements

- Transfer bags across the world easy logistics

- Rigid load method better than

Client Feedback

K.G. Selvan, Plant Manager at Valentine Maritime, added: “We are pleased with the professionalism and technical knowledge of the team at Unique Group.”