Client Name: Deep Dive

Our diving product and service range includes design and manufacture of air, mixed gas and saturation diving equipment, marine winches, certified man-rider winches and specialised subsea rigging equipment.

We offer a wide range of IMCA compliant and classed (Lloyds Register, ABS, DNV) diving equipment and systems, from diver launch and recovery systems (LARS), decompression chambers to containerised air and mixed gas diving systems.

To know more, get in touch with us at diving@uniquegroup.com

Summary of the Project

Unique Group completed the design, manufacture and installation of two 316L wet bell system and associated functional components at Deep Dive, the world’s deepest pool and a ‘Guinness World Records-verified’ venue in Dubai.

Client Requirement

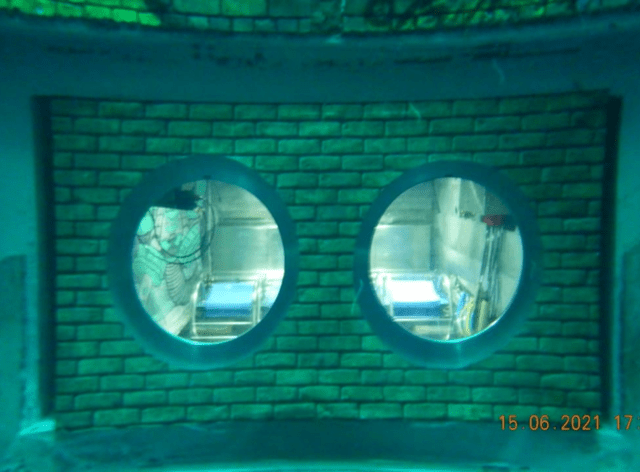

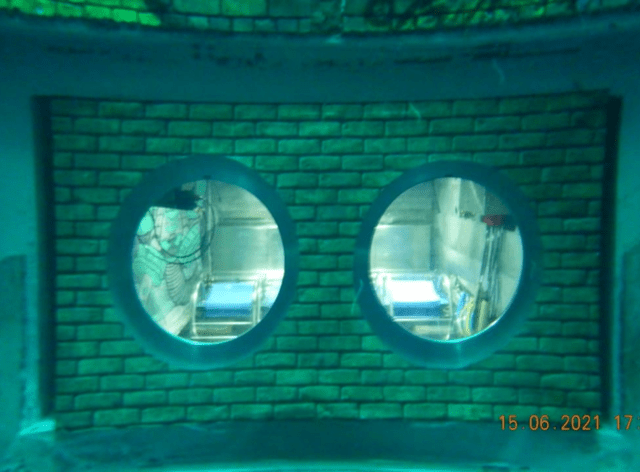

Deep Dive, a diving venue in the UAE which houses the deepest pool in the world, wanted to introduce a dry space area in the form of two static wet bells where divers can rest at 6m and 20m depth in the pool. Unique Group was selected for the project as we have demonstrated the capability to provide a complete turnkey solution from end to end for the client.

Challenges faced

- The water filled pool where the wet bell systems would be placed were already manufactured, so we had to adapt the design of the system to match the space. To ensure accuracy, we employed divers to measure the pool facility as per the surface instruction.

- Completing all the client requirements within the specified time frame while ensuring compliance to international standards and quality requirements. This was efficiently handled by the team through proactive project planning and management.

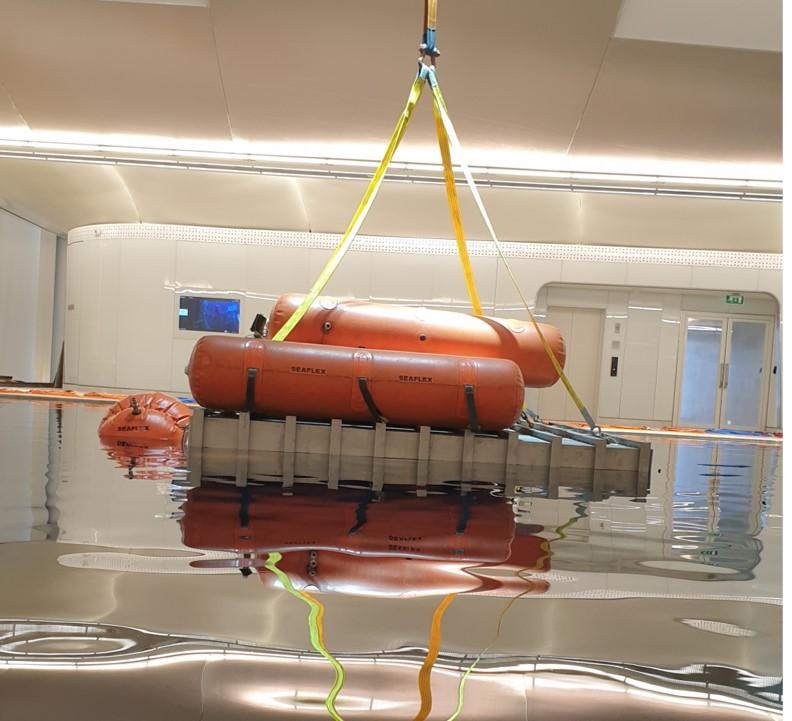

- Installation of the completed SS 316L chambers weighing 5 ton each underwater in the 6-meter depth and 20 meter depth on the specified slot provided for the wet bell. This was managed by the precise maneuvering of the wet bell underwater with the help of surface personnel and divers.

Unique Solution we delivered

After understanding the client’s requirements, Unique Group designed the two 316L Stainless steel static wet bells. The dimensions for the design were provided by the client, in addition to which measurements were also taken with the help of divers underwater.

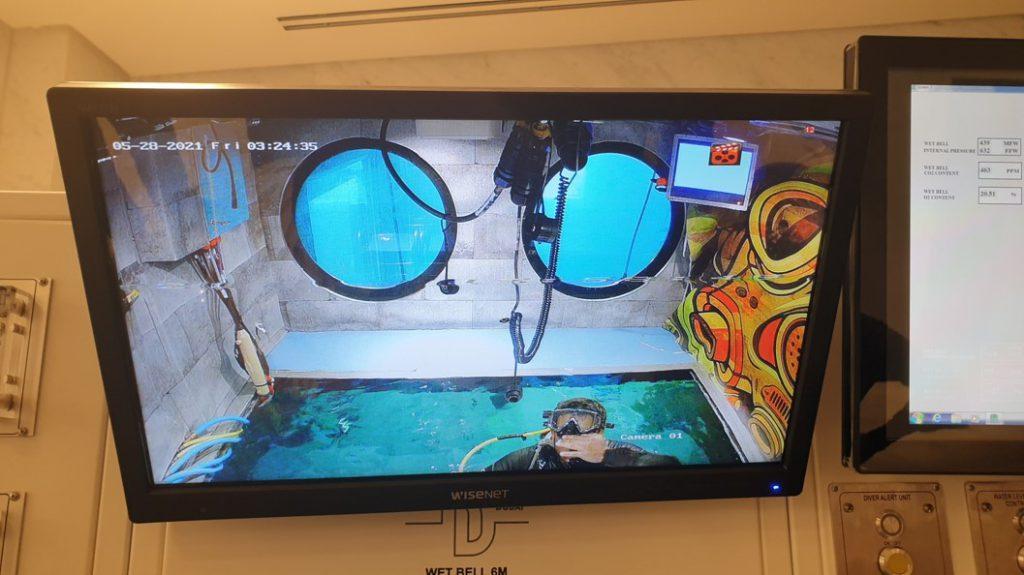

Following the approval of the design by the client, we manufactured the wet bells and the supporting functional component which controls and monitors the wet bell atmosphere. The wet bell system mainly comprises of 3 components, a Pressure Vessel, a Control Panel and Supply & Monitoring Umbilicals. The systems were designed with an internal differential pressure of 0.2 bar taking into consideration the difference between the internal and external pressure acting on the wet bell body. Each wet bell can accommodate a maximum of 4 persons at a time and was built fully compliant to IMCA and ASME standards.

Upon completion of the wet bells and the associated surface control panel, the wet bells were installed underwater in the designated locations in the Deep Dive pool by the divers. This operation was managed by the Unique Group team through proactive planning and communication between the surface personnel and divers, to ensure the smooth maneuvering of the systems during the installation. A combination of our in-house Seaflex buoyancy bags (ALB, MBU and IBU) weighing a total of 3 tons were used by the divers to ensure the wet bell system was positioned to location.

The last part of the project was the commissioning of the surface control system which included the PLC-based automatic operation of the wet bell. The wet bells installed had to be integrated with the control system which monitors the supply of gas, power, and other necessary parameters, to ensure seamless operation for the client.

Benefits delivered

- Customised approach: The wet bells and the surface control panel were customised and built according to the client’s requirements.

- Turnkey project solution: Unique Group managed all aspects of the project from end to end.

- Fully HSEQ compliant with zero incidents

- Fully compliant to IMCA standards

Client Name: Deep Dive

Our diving product and service range includes design and manufacture of air, mixed gas and saturation diving equipment, marine winches, certified man-rider winches and specialised subsea rigging equipment.

We offer a wide range of IMCA compliant and classed (Lloyds Register, ABS, DNV) diving equipment and systems, from diver launch and recovery systems (LARS), decompression chambers to containerised air and mixed gas diving systems.

To know more, get in touch with us at diving@uniquegroup.com