In the complex field of marine and survey operations, selecting the appropriate winch system is crucial for ensuring efficiency, safety, and reliability. A winch system’s capacity and control mechanisms are fundamental factors that influence its performance in challenging environments. This comprehensive guide explores these critical aspects to help you make an informed decision tailored to your specific operational needs.

Key Takeaways

- Winch system capacity should exceed anticipated maximum loads for safety and future needs.

- Drum size and cable length determine operational depth and performance.

- Duty cycle matters for high-frequency or heavy operational workloads.

- Control systems — manual, automatic, and remote — affect precision and safety.

- Modern systems include critical safety features like overload protection and fail-safe brakes.

- Environmental adaptability is essential for marine and corrosive conditions.

- Maintenance accessibility and manufacturer support improve long-term efficiency.

- Total cost of ownership matters more than initial purchase cost.

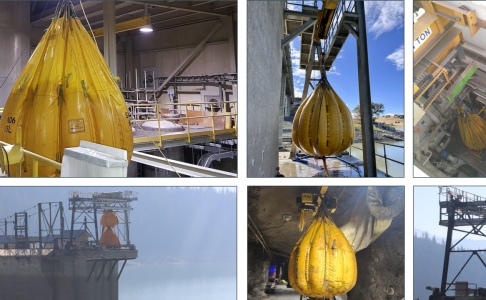

- Unique Group offers reliable winch systems through its marine rental services.

Understanding Winch System Capacity

Capacity is a pivotal factor in the selection of a winch system. It not only refers to the weight the winch can handle but also to the durability and longevity of the system under continuous use. Here’s what you need to consider:

Maximum Load Capacity

The primary consideration is the maximum load capacity, which should align with the heaviest load you anticipate handling. It is advisable to opt for a system that can manage a higher capacity than your current maximum to accommodate potential future needs without compromising safety.

Drum Size and Cable Length

The drum size determines how much cable a winch can house. A larger drum allows for longer cables, which are essential for operations requiring substantial depths. Ensure the cable strength and quality match the intended loads and environmental challenges like underwater currents and saltwater corrosion.

Duty Cycle

Consider the operational intensity your winch system is expected to withstand. High-frequency operations demand a winch with a robust motor and enhanced durability features to handle the rigorous duty cycle without overheating or wear down prematurely.

Exploring Control Systems in Winch Operations

Control systems in winches dictate the precision and safety with which operations can be executed. Modern winches offer various control mechanisms tailored to different operational contexts:

Manual vs. Automatic Controls

Manual controls allow operators direct management over winch activities, suitable for operations where fine adjustments are necessary. Automatic controls, on the other hand, are ideal for standardized lifting where minimal variation is involved, enhancing operational speed and reducing labor costs.

Remote Operation Capabilities

Advanced winch systems often feature remote operation capabilities, allowing operators to manage the winch from a safe distance. This is particularly beneficial in hazardous environments or in situations where direct access to the winch is complicated by operational constraints.

Integrated Safety Features

Modern control systems are equipped with safety features such as overload protection, emergency stop functions, and fail-safe brakes. These features are indispensable in preventing accidents and ensuring the longevity of the winch system.

Additional Considerations for Winch System Selection

Beyond capacity and control, several other factors should influence your choice of winch system:

Environmental Adaptability

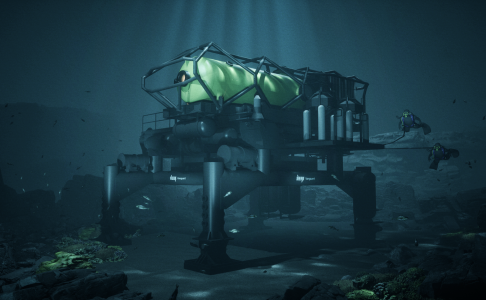

The operating environment plays a significant role in determining the appropriate winch system. Marine operations, for instance, require winches that are built to withstand corrosive saltwater environments and are resilient against the elements.

Maintenance and Support

Opt for a winch system that promises ease of maintenance. Systems designed with accessibility in mind allow for quick repairs and servicing, which minimizes downtime. Additionally, consider the manufacturer’s support and warranty offerings as these can significantly impact the long-term usability of the system.

Cost Efficiency

While initial costs are an important consideration, focusing on the total cost of ownership — including maintenance, operating costs, and potential downtime — can provide a more accurate assessment of the system’s cost efficiency over time.

Conclusion

Choosing the right winch system for your survey operations involves a careful evaluation of capacity, control systems, and several other operational factors. By understanding these key elements, you can select a system that not only meets your immediate needs but also adapts to future requirements.

At Unique Group, we offer a diverse range of marine rental services, featuring some of the most reliable and efficient winch systems designed for various operational needs. Our expertise ensures that you receive not only top-quality equipment but also comprehensive support tailored to your specific circumstances.

Whether you require a rented unit for temporary operations or a fully engineered winch system for long-term deployment, Unique Group delivers proven, reliable solutions. Contact us to specify the best winch system for your project.