Key Takeaways

-

DNV certification ensures global compliance – Systems meet internationally recognized standards (DNV, IMCA, SOLAS) for offshore safety.

-

Life-support functions are built in – Includes CO₂ scrubbers, oxygen supply, medical monitoring, and thermal protection.

-

Certified vs. non-certified systems differ in reliability – Certified units guarantee HRF compatibility, longevity, and reduced operational risks.

-

Lifecycle covers full diver safety – From emergency launch and stabilization to HRF transfer and decompression.

-

Unique Group provides engineered solutions – DNV-certified hyperbaric evacuation systems tailored for oil & gas, defense, and offshore construction industries.

Introduction

In saturation diving, emergencies don’t wait for second chances. A hyperbaric evacuation system serves as a critical link between pressurised dive conditions and surface-level safety.

During accidents such as fire, explosion, flooding, or vessel failure, the only way to safely evacuate saturation divers is to maintain pressure conditions throughout the rescue.

This is where DNV-certified systems make the difference. Unlike basic compliance checkboxes, DNV approval reflects performance under extreme conditions. This ensures systems meet global benchmarks for pressure, safety, and survivability.

What Is a Hyperbaric Evacuation System? Functions and Operational Scope

A hyperbaric evacuation system allows saturation divers to be evacuated while still under pressure. Unlike standard lifeboats, these systems preserve the high-pressure environment needed to protect divers from decompression-related injuries.

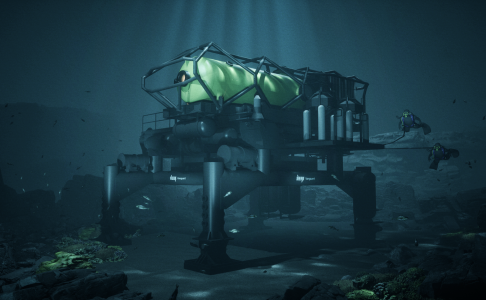

Such systems are deployed in emergencies like onboard fire, explosions, flooding, or instability of the vessel during saturation diving operations. The entire goal is to transport divers safely to a hyperbaric reception facility (HRF) for gradual decompression, without compromising internal pressure or life support.

These systems typically interface directly with diving bells or closed bells, carrying saturation divers to safety in sealed, high-integrity environments.

They are specifically designed to accommodate a defined number of personnel, ensuring that all individuals can be safely evacuated and undergo proper decompression procedures.

Core Components of a Certified Hyperbaric Evacuation Solution

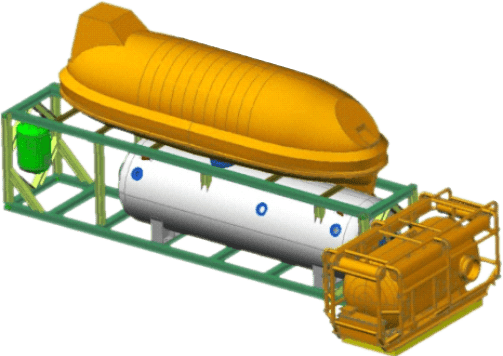

A high-functioning hyperbaric evacuation unit includes several interdependent components designed for redundancy, interoperability, and survivability.

The system is suitable for various scenarios and is designed to accommodate a range of vessels. Provision of ongoing support and maintenance ensures continued reliability and compliance.

Hyperbaric Lifeboat (HLB)

This is the centrepiece of the evacuation system: a pressurised, self-propelled hyperbaric lifeboat built to house saturation divers for up to 72 hours. The lifeboat is divided into compartments to ensure safety and operational efficiency during emergency evacuations.

It includes:

- A pressure-resistant chamber that maintains the same internal pressure as the divers were under during saturation

- Fireproof insulation and self-righting design, so it can survive harsh sea conditions or impact after launch

- Fully autonomous life support systems (oxygen supply, CO₂ scrubbing, environmental controls)

- Integrated communication units to stay in contact with the vessel or onshore facilities

In short, it’s a pressure vessel, lifeboat, and mobile life-support unit all in one, capable of carrying personnel safely in challenging environments.

Closed Bell Transfer System

This enables direct transfer of divers from the closed bell (used in the dive operation) into the HLB without breaking pressure. It typically includes:

- A transfer trunk or mating skirt that seals tightly

- Isolation valves and clamps for safety during handoff

- Built to support both horizontal and vertical bell configurations

The important thing here is uninterrupted pressure continuity. A single lapse in pressure during transfer can be catastrophic. Certified systems are pressure-tested to extreme thresholds during this phase.

Service Connections & Environmental Systems

To ensure 72+ hours of safe survival, the system must maintain optimal living conditions, even in full isolation. These systems include:

- Oxygen injection and storage systems with regulated flow

- CO₂ scrubbers with chemical cartridges or rebreathers

- Temperature and humidity control to prevent condensation, hypothermia, or overheating

- Emergency potable water storage, food rations, and waste containment

These are essential for preventing panic, illness, and system failure during long post-evacuation waits.

Redundant Power and Backup Systems

Certified systems must be equipped with a fail-safe power. This usually includes:

- A primary onboard generator, often diesel-powered

- Battery banks for life support if the generator fails

- Independent power circuits for propulsion, comms, and environmental systems

These systems are required to comply with strict industry regulations to guarantee safety and dependable performance.

The redundancy isn’t just for show. In real incidents, fire or water ingress can knock out power sources, so the system must keep running even with partial failure.

Hyperbaric Reception Facility (HRF) Compatibility

Once the hyperbaric lifeboat (HLB) reaches a safe location, divers need to decompress gradually under supervision. This is only possible if the evacuation system:

- Has standardised flanges and mating collars that connect directly to the HRF

- Maintains compatible pressure ratings and gas service connections

- Supports controlled transfer of divers from the HLB to the hyperbaric reception facility (HRF) without risk of explosive decompression

The system suits a range of vessel types and operational requirements, ensuring flexibility and compatibility.

Systems that fail this handoff can undo all the safety protocols that came before.

Each of these components must be engineered for high load endurance, safety, and rapid deployment in real offshore conditions.

The Significance of DNV Certification: Setting the Global Safety Standard

DNV (Det Norske Veritas) is a recognised authority in marine and offshore safety. DNV certification for hyperbaric evacuation systems is a multi-stage process that validates the system’s integrity and suitability for life-critical operations.

Key areas assessed:

- Pressure integrity and pressure cycling tests under variable load conditions

- Functional redundancy of life support and communication systems

- Fireproofing and explosion resistance

- Human-factor compliance for crew ergonomics and operational controls

- Compatibility with onshore hyperbaric reception facilities

DNV approval meets insurance and legal audit requirements and also signals operational readiness in extreme environments.

DNV-Certified vs. Non-Certified Systems: What’s the Real Operational Difference?

Let’s break it down:

Non-certified systems are sometimes considered as an alternative to DNV-certified solutions, but they lack the safety assurances of certified systems.

| Feature | DNV-Certified | Non-Certified |

|---|---|---|

| Pressure Endurance | Validated under actual offshore conditions | Unverified tolerances |

| Life Support Duration | 72+ hours minimum tested | May lack endurance testing |

| System Compatibility | Certified for interface with HRFs | Interface issues possible |

| Explosion/Fire Resistance | Meets global safety specifications | Varies or undocumented |

| Redundancy | Required across power, communications, and service | May lack critical backups |

| Legal Standing | Audit-ready & insured | Higher liability risk |

The bottom line is that non-certified systems can’t guarantee safety or survival under real emergencies.

The Hyperbaric Evacuation Lifecycle: From Dive to Decompression

Here’s what happens during an actual evacuation triggered by an event such as fire, explosion, or vessel instability:

- Divers are moved from the closed bell into the hyperbaric lifeboat.

- The HLB vessel is launched into the water, even during fire, explosion, or ship tilt.

- Onboard life support takes over: CO₂ scrubbing, oxygen generation, temperature regulation.

- The HLB navigates to the designated hyperbaric reception facility, emphasizing the importance of its ability to reach the site quickly. After arrival, the HLB or rescue vessel is recovered by a standby vessel or support ship.

- Divers are safely transferred and decompressed in a controlled setting.

Throughout this journey, the dive team, vessel crew, and HRF operators must coordinate across systems. Any failure in service connections, generator power, or communications can risk lives.

Unique Group’s DNV-Certified Solutions: Engineered for Extreme Environments

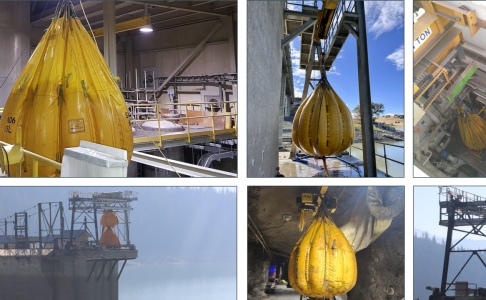

Unique Group delivers fully DNV-certified hyperbaric evacuation systems engineered in the UAE and deployed globally. We offer a comprehensive range of solutions designed to recover and transport hyperbaric evacuation units safely and efficiently.

- Custom modular configurations to suit various vessel sizes and crew capacities

- In-house manufacturing and testing for pressure, load, and fire conditions

- Full integration with existing saturation diving systems

- Global support for installation, training, and audits

Deployed by offshore leaders and trusted by clients operating in the harshest environmental conditions, our systems are built to perform when it matters the most.

Procurement Guidance: What to Look For in a Hyperbaric Evacuation System

A practical checklist for HSE managers and procurement teams.

This procurement checklist supports your hyperbaric evacuation plan by ensuring system compatibility, vessel integration, power redundancy, and dependable life support systems.

- Is the system DNV-certified to applicable codes (e.g. DNV-ST-E406)?

- Supports 72+ hours of life support under pressure?

- Compatible with your saturation diving system and vessel layout?

- Interfaces cleanly with regional HRFs?

- Equipped with redundant power, environmental, and communications systems?

- Includes post-installation support and operational training?

- Is the system equipped for emergency evacuation and decompression?

A single ‘no’ here signals the system is unfit for real-world deployment.

Conclusion

A DNV-certified hyperbaric evacuation system is a necessity. When divers, crew, and clients stake their lives on your system’s performance, nothing less than certified excellence will do.

Unique Group delivers globally compliant, field-tested, and mission-ready hyperbaric evacuation solutions, designed to protect saturation divers from dive to decompression.

Looking to upgrade or audit your system? Contact Unique Group’s team for a technical consultation today.

Frequently Asked Questions (FAQs)

What are the minimum requirements for DNV certification in hyperbaric evacuation systems?

To get DNV certification, hyperbaric evacuation systems must meet standards like DNV-ST-E406, PVHO-1, and ASME for pressure, safety, and material integrity. The process includes design verification, failure analysis, and compliance audits led by DNV.

Can a hyperbaric evacuation system be retrofitted to an older saturation diving vessel?

Yes, Unique Group offers modular systems that integrate with most saturation diving systems, subject to engineering evaluation.

What is the expected endurance of life support systems in a certified HLB?

Typically, a minimum of 72 hours under full crew load, covering oxygen, temperature, and CO₂ scrubbing.

How does the closed bell integrate with the HLB in an emergency?

Via a pressurised transfer system that maintains pressure from the diving bell to the hyperbaric lifeboat.

What after-sales support or training does Unique Group provide for operators and crew?

We offer full lifecycle services, including system audits, operational training, spare parts, and emergency response drills.