Summary of the Project

Unique Group’s Buoyancy and Ballast division assisted the client to tow out the Helwin Alpha Self-Erecting Offshore Transformer Platform which was constructed at Nordic Yards in Germany to Esbjerg in Denmark. Customised Seaflex water-filled bags were as counterweights to add stability to the structure during tow out thus providing equilibrium, control, and correct attitude throughout the process

The platform was successfully towed out and became a part of the HelWin1 cluster wind farm connection project for Dutch transmission grid operator TenneT.

Client Requirement

The client, Siemens, had reached out to Unique Group for a solution to ensure even weight distribution during the tow-out operation.

Challenges faced

We needed to determine the best way to apply counterweights to the platform to balance off the load and ensure no unusual heel angles during the tow. To solve this challenge Unique Group had a series of meetings with Siemens and their appointed tow out contractor SeaRenergy of Hamburg, to choose the optimal solution.

Unique Solution delivered

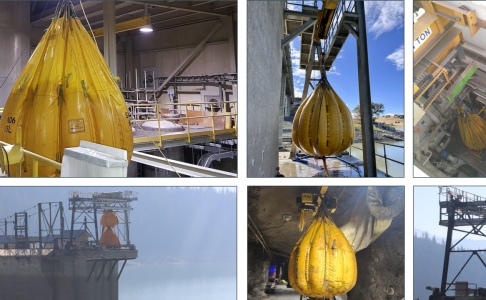

Many different options and scenarios were considered and discussed before the final solution was settled upon, we eventually used 9 x 35t Seaflex brand water-filled bags contained within frameworks sitting on the deck of the platform.

With the solution determined, the manufacture commenced and within a few short weeks the water-filled bags were complete and in Esbjerg awaiting installation. But Unique Group’s involvement in this project did not stop there – our technician was also deployed to the site to assist with the correct installation and operation of the Seaflex branded bags prior to the tow out taking place, successfully, during the late summer of 2013.

Benefits delivered

The alternatives to the solution of water-filled bags that we had used in such an application would generally be large lumps of steel or concrete, which because of their sheer size are difficult and expensive to transport and handle. So, the benefits Unique Group’s Seaflex water bags provided the client are:

- The water bags are easy and economical to pack, transport and stow until required.

- Easy to handle and to rig.

- Easy to fill, owing to the plentiful supply of water unlike other methods

- Easy to remove, pack down and stow once the job is complete.

- Available on a project rental basis.

- Customised solution based on client needs