Leading NDT Machine & System Manufacturers and Suppliers

Unique Group offers a wide range of non-destructive testing equipment with an impressive track record. Their NDT equipment can be used in a wide array of applications used in subsea inspection, maintenance of subsea infrastructure, and detecting subsurface and surface flaws for pipeline configuration. Devices like the ASAMS System 3 are magnetic particle inspection units with continuous ink agitation. Made with stainless steel umbilical hand winch, the product weighs 26 kgs in seawater, which is lighter than its other counterparts.

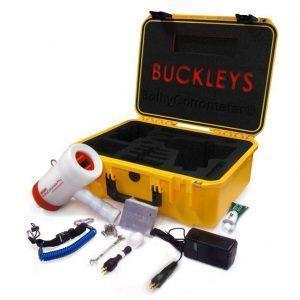

Unique Group has also been associated with brands like Buckleys for products like BathyCorrometer® Pro: Calibration Kit, Complete Kit, Reference Cell, Spark Tester Basic Kit, and more with adjustable output voltage and power limited output for operator safety. The non-destructive testing equipment from Unique Group is the best in the industry for different reasons. These include the following:

- High-quality: We assure you nothing but exceptional quality within a reasonable price point.

- Safety and Customization: All our products come with customizability to meet your unique inspection, repair, and maintenance demands underwater. Whether you are conducting a survey in shallow waters or on the surface, rest assured that our non-destructive testing equipment is manufactured according to industry standards.

- Extensive Product Inventory with top-of-the-line features: Our ASAMS System 3 Magnetic Particle Inspection Unit is a versatile and user-friendly unit, capable of performing both AC and DC magnetization. It features a high-resolution display and an ergonomic design, making it easy to use even in challenging environments. In addition, we also have other products like reference cells, calibration kits, and spark tester kits.

Our range of Non-Destructive Testing equipment at Unique Group is designed to meet the highest industry standards, providing accurate and reliable results for surveyors in a range of industries. Whether you need Magnetic Particle Inspection Units, Calibration Kits, Reference Cells, or any other NDT equipment, we have the right non-destructive equipment for the job.