Client Name: An offshore & marine engineering solutions company

Summary of the Project

Unique Group successfully executed a record-breaking 2420-ton water bag load test at a shipyard in South Texas, testing a 2200mt Leg Encircling Crane on the first Jones Act-compliant Wind Turbine Installation Vessel. This complex project required meticulous planning, logistics coordination, and rigorous safety management to ensure seamless execution, setting a benchmark in crane load testing across the Americas region.

Client Requirement

A leader in offshore and marine engineering solutions, required a proof load test for their newly built Wind Turbine Installation Vessel, ensuring its crane could handle designated loads safely. The test had to comply with strict industry standards and regulatory requirements while maintaining the highest safety measures. The project required:

- A 2420-ton load test using water-filled Water Weights load test bags.

- Collaboration with OEMs and class surveyors to validate the lift plan and load test procedure.

- A controlled and gradual load application to prevent instability or equipment failure.

Challenges Faced

Complex Logistics and Resource Mobilization

- Coordination of high-capacity water bags and load testing equipment from multiple global locations.

- Managing customs clearance and timely delivery of specialized components.

- Deploying trained and certified technicians from multiple regional offices to the job site.

Space and Load Distribution Constraints

- Ensuring proper load application within the crane’s structural limits.

- Addressing potential risks associated with the floating spreader beam arrangement.

Unique Solution Delivered

Unique Group provided a turnkey load testing solution, managing all aspects from equipment procurement to execution. Key aspects of the solution included:

- Custom Lift Plan Development: We designed a specialised lift plan and load test procedure in collaboration with Seatrium, the crane OEM, and classification surveyors to ensure successful load test execution and safely deliver the expected results.

- Specialized Equipment Procurement: Given the scale of the load being tested, many high-capacity water bags were needed, along with heavy-duty slings, spreader beams, shackles, and load monitoring devices which were sourced from local and international suppliers.

- Competent Technical team: Ensuring that the right technical expertise was available on-site at the right time was another vital component of the planning. To address this, trained, experienced and competent technicians from several regional offices were mobilized and deployed to the job site in advance of the test date. Each team member was assigned specific responsibilities, ranging from managing the rig-up of slings, spreaders and test load bags to overseeing the proper placement and installation of certified and calibrated load monitoring equipment. This cross-regional approach was fundamental to the smooth operation of the test, as it ensured that local knowledge and expertise were incorporated into the execution phase.

- Safety and Risk Management: Before mobilizing the team to the shipyard, a comprehensive safety review and risk assessment were conducted. This assessment identified potential hazards and provided mitigation strategies for addressing these risks. The plan encompassed safety precautions specific to the crane load testing environment, such as the potential for equipment failure, human error, and environmental factors such as weather conditions. By emphasizing safety as the overriding priority throughout the planning and execution phases, the project was able to proceed without major incidents.

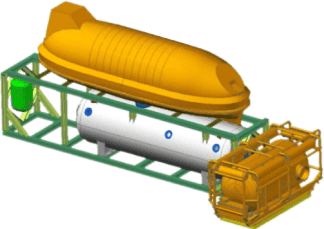

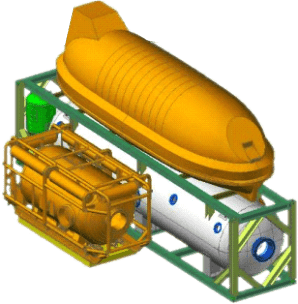

- Floating Spreader Beam Arrangement: Unique Group utilised this arrangement to evenly distribute the applied load and prevent structural imbalances. This configuration involved positioning the spreader beams in such a way that they provided an even distribution of weight across the crane’s lifting points. The floating nature of the spreader beam setup added an additional layer of complexity, requiring close monitoring of load distribution throughout the test.

- Advanced Load Monitoring: As the water bags were incrementally filled with water to simulate the necessary load, it was crucial to maintain a balanced load throughout the entire process. Any deviation from this balance—whether due to uneven water distribution or shifting loads—could cause significant issues. An out-of-balance load in such a setup could lead to catastrophic failure, such as structural damage or instability in the crane. Therefore, real-time monitoring utilizing certified flow meters to monitor and manage the distribution of load was essential during the filling process.

Throughout this process, the team maintained constant communication, regularly reviewing the load data to make real-time adjustments if necessary. This ongoing collaboration ensured that the crane’s performance underload could be assessed thoroughly, while maintaining strict control over the risks associated with an unbalanced load.

The floating spreader beam arrangement, while highly effective for load distribution, required heightened attention to detail during each phase of the load application. This careful, methodical approach allowed the team to manage the complexity of the test and verify the crane’s structural integrity successfully under maximum load conditions.

Benefits Delivered

-

Successful Proof Load Testing: Verified the operational integrity of the 2200mt crane, ensuring compliance with industry standards.

-

Seamless Execution Without Incident: The test was conducted safely and efficiently, with no major disruptions or safety incidents.

-

Industry Benchmark Achievement: The largest water bag load test in the Americas, reinforcing Unique Group’s expertise in high-capacity crane testing.

-

Future Application Potential: The methodologies and lessons learned from this project can be applied to similar offshore wind and heavy-lift infrastructure projects.

This landmark crane load test demonstrates Unique Group’s ability to execute large-scale proof load tests with precision, safety, and efficiency. By combining advanced engineering solutions, strategic collaboration, and rigorous risk management, Unique Group successfully validated the crane’s performance under extreme loads, setting a new standard for load testing in offshore wind and marine projects.

Client Name: An offshore & marine engineering solutions company