In the realm of subsea exploration and engineering support, commercial saturation diving equipment stands as a testament to human ingenuity and engineering marvel. Unique Group, a leading manufacturer in the field of commercial diving equipment, has played a pivotal role in crafting these systems, ensuring safety, precision, and unrivaled efficiency in deep-sea operations.

Commercial saturation diving equipment is a sophisticated system, engineered for deep-sea operations that require divers to remain at substantial depths for extended periods. It comprises various components, each with a crucial role to play in ensuring the safety and effectiveness of the mission. Let’s delve into the different parts of the system and the key considerations needed when manufacturing these complex setups.

- Pressure Vessel: At the heart of the saturation diving system is the pressure vessel. This chamber serves as a living space for divers, maintaining the appropriate pressure and life support systems. Compliance, quality, and durability are paramount in its construction, ensuring it can withstand immense pressures and harsh operating environments.

- Bell Systems: The diving bell is a critical component for transporting divers between the surface and the worksite. It is airtight and equipped with gas, power, cameras, and communication systems to keep the divers safe and connected to the surface.

- Umbilical System: The umbilical system consists of hoses and cables that supply breathing gas, hot water, communications, and electrical power to the divers. The system’s materials must be manufactured to withstand the harsh environment, as they are essential for the safety and productivity of the divers.

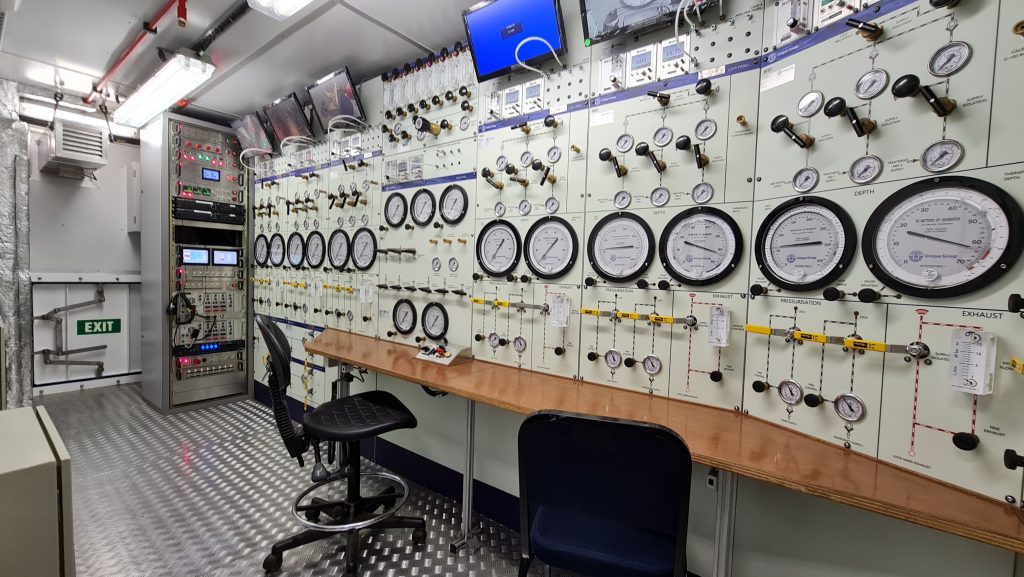

- Gas Management System: A gas panel manages the mixture of breathing gases for the divers. Accurate gas control is essential to prevent decompression sickness and maintain diver health. The panel must have redundancy to ensure diver safety.

- Dive Control Console: Dive Control is the operational nerve center of the system. It allows surface personnel to monitor and control the entire saturation diving operation, including gas mixtures, communication, and environmental controls.

- Environmental Control System: The environmental control system maintains the living conditions within the pressure vessel, including temperature, humidity, and carbon dioxide levels. This system plays a crucial role in ensuring the health and comfort of divers.

When designing and manufacturing commercial saturation diving equipment, several critical factors should be considered. A few of the key factors are below:

- Material Selection: Materials used must be corrosion-resistant and durable, as they will be exposed to harsh underwater conditions for extended periods.

- Safety Features: Redundancy and fail-safe mechanisms should be integrated into all systems to ensure the safety of the divers and the success of the mission.

- Precision Engineering: High-precision manufacturing is crucial to meet the stringent requirements of saturation diving, as even minor faults can have significant consequences.

- Testing and Certification: Rigorous testing and adherence to industry standards are essential to ensure that the equipment meets safety and performance criteria.

- Customization: Each saturation diving system should be tailored to the specific needs of the mission, taking into account factors such as depth, duration, and environmental conditions.

In conclusion, commercial saturation diving equipment is a marvel of engineering that allows humans to explore the depths of the oceans and perform critical underwater tasks.

Unique Group has over 30 years of experience in crafting these systems, ensuring precision, safety, and reliability. The intricacies of these systems, coupled with the stringent manufacturing standards, make saturation diving equipment a testament to human capability and innovation in the depths of the ocean. You can see our range of solutions here.