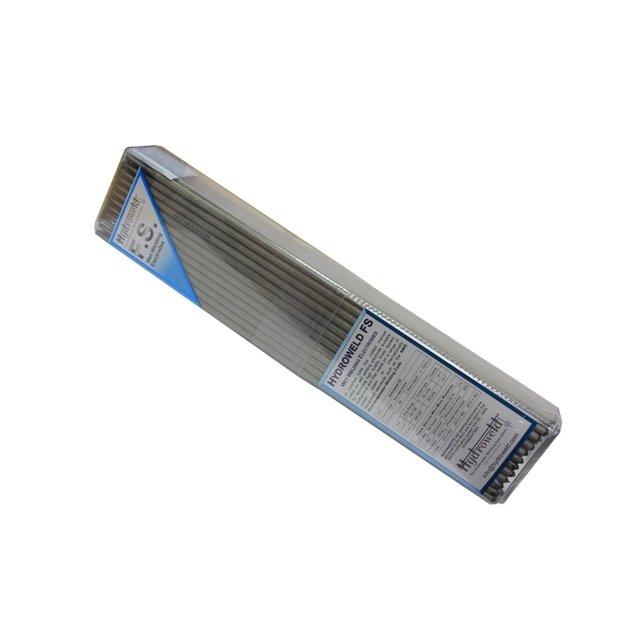

Hydroweld: Welding Rods

Unique Group supplies Hydroweld, Welding Rods, the result of more than five years of research and development into flux formulas, filler metals, and extra coatings. Designed to work in all positions in freshwater or brine to a depth of 100 metres, and their superior user-friendly qualities and wet welding characteristics make it simple to produce high-quality wet welds that meet international requirements.

Features

General purpose wet welding electrodes

Finely rippled, well-shaped beads

Self-releasing slag

Enhanced rutile flux coated

Optimum size for easy manipulation

Specifications

Welding Rods FS, Hydroweld, 3.2 mm: D-ST-166

Welding Rods FS, Hydroweld, 4mmx 350mm, 60 pieces: D-ST-167

Available in 3.2 mm x 350 mm long and are sold in boxes of 90 electrodes or 4 mm x 350 mm and are sold in boxes of 60 electrodes and/or cartons of 5 boxes.

Formal wet welding procedures and welder qualifications to internationally recognised specifications such as the AWS D3.6M-99.

Applications

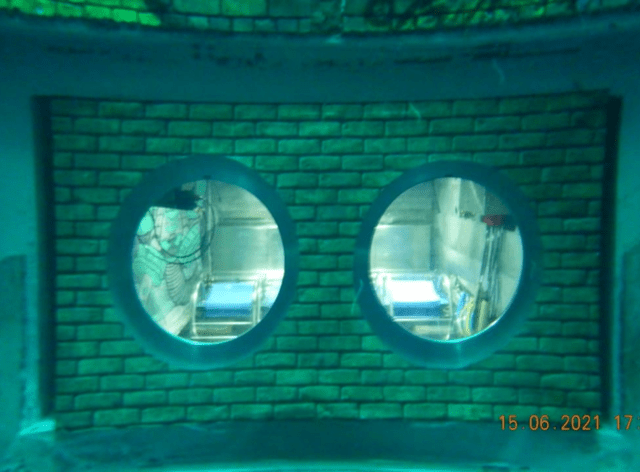

Ability to be utilised in all positions in fresh or brine water to a depth of 100 metres

Used for subsea tooling