This article breaks down the full lifecycle of offshore decommissioning — from stakeholder planning to seabed restoration — with a focus on ESG, safety, and technical precision.

Key Takeaways

-

Offshore decommissioning is a multi-phase process from planning to post-monitoring.

-

Each stage demands strict environmental, safety and regulatory compliance.

-

Well abandonment ensures leak-proof sealing before any structural dismantling.

-

Unique Group supports decommissioning with geophysical surveys, USVs, and Uni-FlowX — a mass flow excavation system.

-

Seabed restoration and audit processes reinforce ESG and long-term sustainability goals.

-

Success depends on technical expertise, stakeholder coordination, and specialised equipment.

Introduction

Dealing with ageing offshore infrastructure is a responsibility for all asset owners. And that responsibility comes with technical, environmental, and regulatory stakes that can’t be ignored.

This article walks you through the complete offshore decommissioning process, broken down into 7 actionable steps – from early planning and well abandonment to seabed restoration and final reporting . You will discover what it takes, why it matters, and how the right engineering partner can make all the difference.

For a practical breakdown of how Unique Group delivers safe and cost-efficient decommissioning in real-world projects, read our detailed guide here.

Why Offshore Decommissioning Matters

As the global energy sector transitions and infrastructure reaches the end of its useful life, decommissioning is becoming an operational and regulatory priority. Across the North Sea, Pacific Region, and beyond, existing offshore oil and gas platforms demand safe, responsible dismantling.

But this isn’t just about removal. It requires protecting the marine environment, ensuring regulatory compliance, minimising cost, and optimising asset value wherever possible.

With the right approach and support from expert partners like Unique Group, offshore decommissioning services can become an opportunity to reinforce your commitment, capability and efficiency.

Here’s a step-by-step walkthrough of how the process works and where Unique Group can support your operations.

Step 1: Planning and Regulatory Consultation

Before a single bolt is removed, companies must engage in in-depth planning and consultation. This involves:

- Reviewing active leases and field status.

- Engaging with regulators under frameworks like the Petroleum Act.

- Conducting initial site surveys.

- Establishing environmental baselines.

- Reviewing existing asset condition and identifying idle infrastructure.

- Cost modelling, project scoping, and establishing clear expectations around safety, environmental effects, and offshore infrastructure limitations.

- Coordinating with operators, conducting stakeholder reviews, and establishing protocols for hazardous materials and disposal routes, including onshore recycling and waste treatment pathways.

Major stakeholders involved:

- Internal engineering teams.

- Environmental compliance officers.

- Government regulatory agencies.

- Third-party decommissioning solution providers.

Unique Group helps with preparatory works, offering geophysical and geotechnical site assessments through surveys to support early-stage compliance and risk mitigation.

Step 2: Engineering Surveys and Site Assessments

Once the legal groundwork is laid, it’s time for the technical inspection of the offshore infrastructure. At this stage, operators assess:

- Subsea pipelines, conductors, and risers.

- Gas platforms and jacket structures.

- Risks to nearby ecosystems and the seabed.

- Accessibility for platform removal and equipment deployment.

Unique Group utilises a comprehensive portfolio of services and equipment to deliver accurate assessments, inspections, and ROV operations using trusted brands like Kongsberg, Cygnus, Edgetech®, Nortek, and SAAB Seaeye.

Additionally, our advanced Unmanned Surface Vessels (USVs) — including the Uni-Pact and Uni-Max — are deployed for hydrographic and geophysical surveys in deep offshore environments. These USVs enhance safety and optimise operational costs by reducing the need for crewed operations and providing high-precision data.

With more than 250 in-house engineers and the capability to deploy custom tooling for difficult conditions, Unique Group excels in adapting to diverse offshore rigs, water depths, and environmental constraints.

Step 3: Plugging and Abandoning Offshore Pipelines

Before any subsea structure is removed, offshore wells must be safely plugged and pipelines decommissioned to prevent post-operational leakage of hydrocarbons into the marine environment.

Well abandonment generally involves:

- Installing cement plugs and mechanical barriers.

- Isolating gas wells and oil reservoirs.

- Pressure testing and long-term stability analysis.

Unique Group provides:

- Pipeline environmental sealing systems.

- Engineered clamps and recovery tools.

- Compliance support for local and international abandonment regulations.

This phase also involves coordination with regional and national regulators to submit abandonment reports and closure documentation. These reports become part of the final government decommissioning work dossier.

Unique Group has over two decades of experience in building customised clamps, decommissioning tools and seals. We work with clients in understanding their specific needs, then we design, manufacture, test and install these products.

Step 4: Topside Dismantling and Equipment Removal

With the wells safely abandoned, operators shift focus to dismantling the topside structures — the above-water portions of the platform.

This stage often involves managing a range of structures, including gas platforms, drilling towers, and housing facilities. Proper classification and routing of dismantled materials is essential. Important activities include:

- Disconnection of utilities, living quarters, and production facilities.

- Removal and labelling of critical systems for onshore disposal or re-use.

- Hazardous material control and transfer to licensed disposal centres.

Unique Group’s IMCA-compliant buoyancy equipment, including Seaflex® Air Lift Bags, supports heavy lifts safely and efficiently. Our industry-compliant diving solutions such as Launch and Recovery Systems ( LARS) and associated dive systems, play a key role at this stage. All dismantling follows strict safety protocols to protect personnel, infrastructure, and the marine environment.

Recycling and re-use options are considered where possible, reducing cost and waste. Components may be reconditioned for future use or sent to onshore treatment facilities.

Careful planning also ensures environmental protection throughout dismantling and platform removal, minimising disruptions to the marine environment and preserving marine life where applicable.

Step 5: Platform Removal and Subsea Decommissioning

The next challenge is decommissioning offshore structures, which includes the removal of submerged components. This phase typically includes

- Cutting and recovering pipelines, mattresses, and jackets.

- Managing complex offshore platform decommissioning procedures.

- Deciding between partial removal or full extraction based on project goals and regulations.

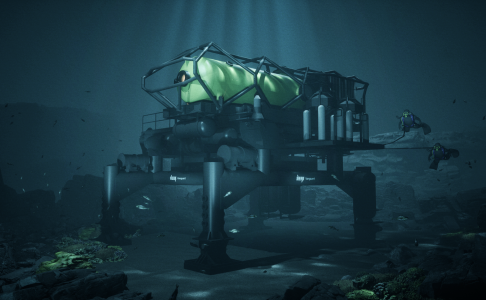

Unique Group’s innovations like Uni-FlowX, a non-contact excavation system equipped with a subsea digger, improve seabed access while minimising ecological disruption. When paired with pipeline and umbilical recovery systems, it simplifies one of the most technically demanding phases of the project.

Read more to see how Uni-FlowX helped projects in South East Asia, Malaysia and Bangladesh.

In some cases, decommissioned platforms may be converted into artificial reefs – an environmentally responsible disposal method – pending regulatory approval.

Step 6: Seabed Clearance and Marine Restoration

Clearing and restoring the seabed is a vital part of maintaining ocean health and satisfying regulatory requirements. This phase includes:

- Debris identification and recovery.

- Sediment sampling and pollution checks.

- Final verification by regional supervisors.

Unique Group’s specialised subsea tools – such as Uni-FlowX, a mass flow excavation system, along with dredging systems and survey tools – enable efficient seabed cleaning with minimal disturbance.

By restoring the site to a clean and safe condition, oil and gas companies reinforce their commitment to protecting the marine environment and fulfilling long-term corporate responsibility goals.

Step 7: Post-Decommissioning Monitoring and Final Reporting

Long after the platform is gone, operators must continue to show accountability.

- Periodic site surveys and ecosystem monitoring.

- Final audit reporting to government and regulatory bodies.

- Managing liability through reporting, documentation, and insurance.

Unique Group offers tailored environmental monitoring solutions, technical support, and compliance consulting. This ensures operators can prove that their decommissioning was done responsibly and safely.

These post-closure activities are trust-building exercises that reassure both the public and industry regulators.

Safety Protocols and Compliance Emphasis

Offshore decommissioning involves handling heavy equipment, managing hazardous materials, and operating in volatile marine environments. Unique Group follows internationally recognised safety standards and IMCA (International Marine Contractors Association) guidelines to ensure the health and protection of all personnel and assets.

Major safety and compliance measures include:

- Strict adherence to country-specific and global offshore regulatory frameworks.

- Use of certified lifting, dismantling, and recovery equipment.

- Implementation of HSE (Health, Safety, Environment) audits and safety drills.

- Detailed risk assessments before every critical operation.

- Comprehensive training and PPE protocols for all field engineers and operators.

Conclusion

What is offshore decommissioning?

Offshore decommissioning is the safe, regulated process of retiring and removing offshore oil and gas structures at the end of their operational life, while protecting the environment and complying with international and local regulations.

Learn more about how Unique Group delivers safe and cost-effective decommissioning solutions.

It’s a multi-phase responsibility involving safety, engineering, technology, environmental stewardship, and regulatory compliance.

From early planning to platform removal and post-decommissioning monitoring, offshore decommissioning is a complex, high-stakes operation. With increasing scrutiny on the energy section, oil and gas operators must choose trusted partners who offer global expertise and local execution.

Unique Group delivers full-scope offshore decommissioning solutions, including:

- Compliance with evolving regulations.

- High-stake asset recovery across the outer continental shelf.

- Engineering excellence for the gas industry and offshore oil operators.

- End-to-end support that balances cost, safety, and the environment.

- Experienced technical team to support the projects from start to finish at any global location.

Ready to plan your offshore decommissioning project? Our engineers and project specialists are here to support you from start to finish — with full-scope services that ensure compliance, safety, and cost efficiency.

Fill in our short enquiry form on the Contact Us page, and our offshore decommissioning experts will be in touch to guide you through tailored next steps.

Frequently Asked Questions

What is Offshore Decommissioning?

Offshore decommissioning is the structured process of safely retiring and dismantling offshore oil and gas production facilities once they reach the end of their operational life.

How can Unique Group support in Decommissioning?

Unique Group provides end-to-end support across all decommissioning phases — from early planning and well abandonment to platform removal and final reporting — using expert engineering teams, certified equipment, and proven methodologies.

What does the offshore platform decommissioning procedure include?

It includes regulatory planning, well abandonment, topside dismantling, subsea structure removal, seabed restoration, and post-decommissioning monitoring.

How long does decommissioning take?

The timeline ranges from a few months to several years, depending on factors such as water depth, platform size, regional regulations, and environmental complexity.

Are decommissioned structures reused?

Yes. Some structures are repurposed as artificial reefs, while others are recycled or reused in different offshore operations, depending on conditions and approvals.

How is the marine environment protected during decommissioning?

By miminising seabed disturbance, sealing wells properly, applying pollution control measures, and conducting ongoing site monitoring to ensure marine ecosystem health.