UG ERS 350: Mag Environmental Regeneration System

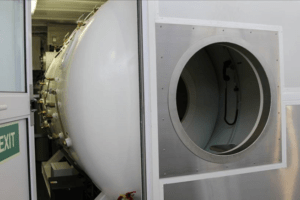

Unique Group offers ERS 350 magnification, a quiet, reliable and multi-configurable external gas regeneration system for Saturation Diving. The unit consists of a robust frame/skid, located within an ergonomic cabinet with access hatches. The ERS350 Mag is designed to circulate gas from inside the chamber environment and through a scrubber.

Unique Group offers ERS 350 magnification, a quiet, reliable and multi-configurable external gas regeneration system for Saturation Diving. The unit consists of a robust frame/skid, located within an ergonomic cabinet with access hatches. The ERS350 Mag is designed to circulate gas from inside the chamber environment and through a scrubber.

Features

The unit is remotely operated from the chamber and connects to SCBA Supply.

Connected to each chamber environment using pipes and fittings.

It also controls humidity in the chamber by condensing water vapour and heating and cooling the atmosphere.

Features a hermetically sealed high efficient, low maintenance blower.

Specifications

Length: 2075mm

Width : 1360mm

Height : 2050mm

Mass: +/- 1700 kg

Lifting: 4 removable eye-bolts

Applications

This unit is designed to circulate gas from inside the chamber environment and through a scrubber.

Controls the humidity and maintains the chamber’s temperature.