Diving + Life Support

A world leader in the design and manufacture of diving and life support equipment.

Operated today by customers around the world.

Industries

we are proud to serve.

Renewable Energy

Medical

Defense

Military + Aviation

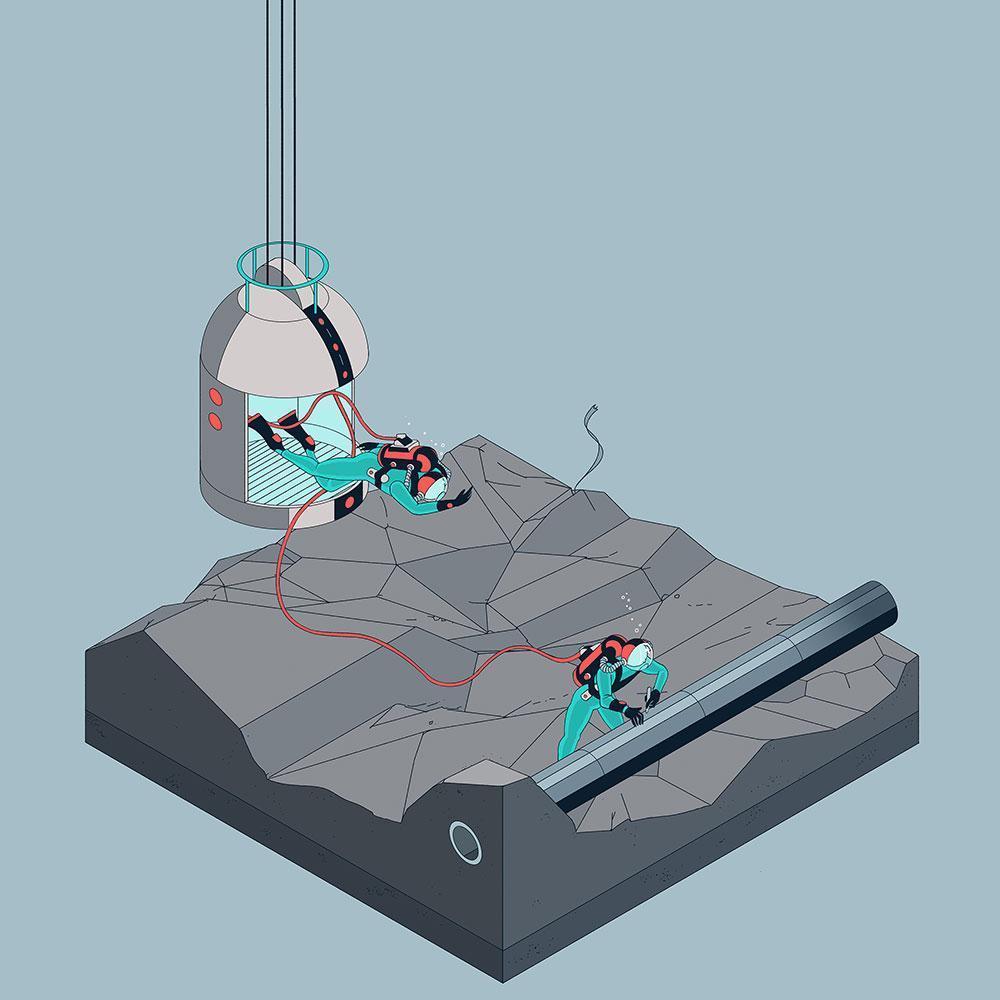

We provide customised, state-of-art intervention and support solutions, including surveillance and detection solutions, rapid response and global capability for emergency responses. Our solutions are used for both commercial and military applications. Our capabilities include search, salvage, ordinance recovery, disabled submarine life extension, escape support and survivor rescue using the below methodologies.

Saturation Diving Equipment

We’ve a long and proud track record in the manufacture of classed saturation diving systems. We provide custom DSV saturation, portable and HRF saturation systems, while we also supply bell and chamber life support equipment and other key ancillary kit.

Surface Diving Equipment

Our industry-leading, IMCA-compliant systems and equipment can be supplied as non-classed or classed. The complete product packages feature containerised chambers, machinery and control rooms with Launch and Recovery systems for air diving baskets, wet-bells and twin basket units.

General Diving Equipment

From personal diving equipment and consumables to dive panels and winches, we’re primed to provide everything you need for your diving operations. And we possess the resources and geographical reach to provide them swiftly, wherever they’re required.

Medical Technology

With decades of specialist experience, we offer a new proposition in hyperbaric treatment through the design, manufacture and supply of bespoke, multi place hyperbaric oxygen treatment chambers, with you, and your patients in mind. We provide expert support to integrate your hyperbaric oxygen treatment chamber into your medical infrastructure, working alongside your architects, doctors and project managers.

Specialised Boats

We’re a proven market leader in the design, construction and maintenance of self-propelled hyperbaric lifeboats and specialist offshore vessels. And we complement our service offering with expert inspection, repair and maintenance services.

Looking to buy or rent Diving and Life Support Equipment?

Talk to our specialists and find the best solution for your needs.

Some Practical Applications of Diving + Life Support

Our survey equipment is trusted across diverse marine applications.

Sign Up To Our Newsletter

Stay updated with the latest innovations, case studies, and industry insights from Unique Group.