Survey Equipment

Primed to provide the products you need.

Wherever and whenever you need them.

Sales and rental options – so you get the optimum package.

Industries

we are proud to serve.

Renewable Energy

Oil + Gas

Marine

Our Survey Equipment Solutions

Comprehensive range of advanced survey equipment for all your marine operations

ROV Equipment

We provide state-of-the-art ROV equipment, supporting all aspects of offshore operations – including 24/7 specialist advise and support, across all stages of your project.

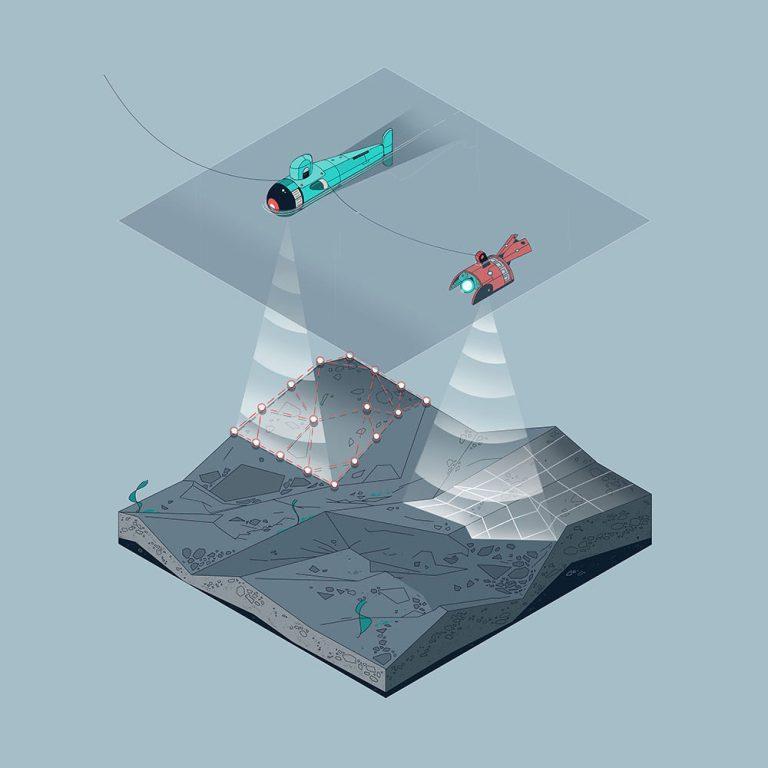

Hydrography

Specialists in hydrographic survey equipment, we offer an extensive product-portfolio to assist with various subsea survey operations. Our products are available for rental and sale, from various locations across the globe.

Inspection, Repair and Maintenance (IRM)

Our comprehensive range of inspection equipment conducts all your subsea and topside inspection programmes. Our trusted equipment, available for rent and sale, assists with projects across the offshore renewables, oil + gas and marine industries. We provide specialist advice and support – 24 hours and 7 days a week – before, during and after your project.

Oceanographic and Environmental

Our leading oceanographic and environmental survey solutions provide you with a cost-effective and competitive advantage. The specialists at Unique Group are primed to support you 24/7 from full service centres across the globe.

Geophysical

Our wide range of geophysical survey equipment caters to various applications, assisting you with various types of projects, including marine construction, site surveys, search and recovery, and many more. Our products are available for rental and sale, from various locations across the globe.

Subsea Positioning

Our extensive range of subsea positioning equipment supports all aspects of offshore operations, to provide high accuracy for survey and construction projects. For the marine market, our track record encompasses operations in ports and harbours, offshore renewables, cable installation and civil construction.

Surface Vessel Equipment

Our comprehensive range of surface vessel equipment is routinely augmented by the latest technology to ensure we have the solution you need. Our products are available for rental and sale, from various locations across the globe.

Survey Field Services

Our professionally trained Subsea Survey Engineers and Technicians are now available to provide expert support for our clients in the field anytime and everywhere across the globe.

Looking to buy or rent Unmanned Surface Vessels?

Talk to our specialists and find the best solution for your needs.

Practical Applications

Our survey equipment is trusted across diverse marine applications

Sign Up To Our Newsletter

Stay updated with the latest innovations, case studies, and industry insights from Unique Group.